Example with wells

This example demonstrates how to set up a 3D domain with a layered permeability field, define wells and solve a simple production-injection schedule. We begin by loading the Jutul package that contains generic features like grids and linear solvers and the JutulDarcy package itself.

Preliminaries

using JutulDarcy, JutulJutulDarcy uses SI units internally. It is therefore convenient to define a few constants at the start of the script to have more managable numbers later on.

Darcy, bar, kg, meter, day = si_units(:darcy, :bar, :kilogram, :meter, :day)(9.86923266716013e-13, 100000.0, 1.0, 1.0, 86400.0)Defining a porous medium

We start by defining the static part of our simulation problem – the porous medium itself.

Defining the grid

The first step is to create a grid for our simulation domain. We make a tiny 5 by 5 grid with 4 layers that discretizes a physical domain of 2000 by 1500 by 50 meters.

nx = ny = 5

nz = 4

dims = (nx, ny, nz)

g = CartesianMesh(dims, (2000.0, 1500.0, 50.0))CartesianMesh (3D) with 5x5x4=100 cellsAdding properties and making a domain

The grid by itself does not fully specify a porous medium. For that we need to specify the permeability in each cell and the porosity. Permeability, often denoted by a positive-definite tensor K, describes the relationship between a pressure gradient and the flow through the medium. Porosity is a dimensionless number between 0 and 1 that describes how much of the porous medium is void space where fluids can be present. The assumption of Darcy flow becomes less reasonable for high porosity values and the flow equations break down at zero porosity. A porosity of 0.2 is then a safe choice.

Jutul uses the DataDomain type to store a domain/grid together with data. For porous media simulation, JutulDarcy includes a convenience function reservoir_domain that contains defaults for permeability and porosity. We specify the permeability per-cell with varying values per layer in the vertical direction and a single porosity value for all cells that the function will expand for us. From the output, we can see that basic geometry primitives are also automatically added:

nlayer = nx*ny # Cells in each layer

K = vcat(

repeat([0.65], nlayer),

repeat([0.3], nlayer),

repeat([0.5], nlayer),

repeat([0.2], nlayer)

)*Darcy

domain = reservoir_domain(g, permeability = K, porosity = 0.2)DataDomain wrapping CartesianMesh (3D) with 5x5x4=100 cells with 17 data fields added:

100 Cells

:permeability => 100 Vector{Float64}

:porosity => 100 Vector{Float64}

:rock_thermal_conductivity => 100 Vector{Float64}

:fluid_thermal_conductivity => 100 Vector{Float64}

:rock_density => 100 Vector{Float64}

:cell_centroids => 3×100 Matrix{Float64}

:volumes => 100 Vector{Float64}

235 Faces

:neighbors => 2×235 Matrix{Int64}

:areas => 235 Vector{Float64}

:normals => 3×235 Matrix{Float64}

:face_centroids => 3×235 Matrix{Float64}

470 HalfFaces

:half_face_cells => 470 Vector{Int64}

:half_face_faces => 470 Vector{Int64}

130 BoundaryFaces

:boundary_areas => 130 Vector{Float64}

:boundary_centroids => 3×130 Matrix{Float64}

:boundary_normals => 3×130 Matrix{Float64}

:boundary_neighbors => 130 Vector{Int64}Defining wells

Now that we have a porous medium with all static properties set up, it is time to introduce some driving forces. Jutul assumes no-flow boundary conditions on all boundary faces unless otherwise specified so we can go ahead and add wells to the model.

A vertical producer well

We will define two wells: A first well is named "Producer" and is a vertical well positioned at (1, 1). By default, the setup_vertical_well function perforates all layers in the model.

Prod = setup_vertical_well(domain, 1, 1, name = :Producer);A single-perforation injector

We also define an injector by setup_well. This function allows us to pass a vector of either cell indices or tuples of logical indices that the well trajectory will follow. We setup the injector in the upper left corner.

Inj = setup_well(domain, [(nx, ny, 1)], name = :Injector);Choosing a fluid system

To solve multiphase flow with our little toy reservoir we need to pick a fluid system. The type of system determines what physical effects are modelled, what parameters are required and the runtime and accuracy of the resulting simulation. The choice is in practice a trade-off between accuracy, runtime and available data that should be informed by modelling objectives. In this example our goal is to understand how to set up a simple well problem and the ImmiscibleSystem requires a minimal amount of input. We define liquid and gas phases and their densities at some reference conditions and instantiate the system.

# Set up a two-phase immiscible system and define a density secondary variable

phases = (LiquidPhase(), VaporPhase())

rhoLS = 1000.0

rhoGS = 100.0

rhoS = [rhoLS, rhoGS] .* kg/meter^3

sys = ImmiscibleSystem(phases, reference_densities = rhoS)ImmiscibleSystem with LiquidPhase, VaporPhaseCreating the model

The same fluid system can be used for both flow inside the wells and the reservoir. JutulDarcy treats wells as first-class citizens and models flow inside the well bore using the same fluid description as the reservoir, with modified equations to account for the non-Darcy velocities. We call the utility function that sets up all of this for us:

model, parameters = setup_reservoir_model(domain, sys, wells = [Inj, Prod])

modelMultiModel with 4 models and 6 cross-terms. 221 equations, 221 degrees of freedom and 801 parameters.

models:

1) Reservoir (200x200)

ImmiscibleSystem with LiquidPhase, VaporPhase

∈ MinimalTPFATopology (100 cells, 235 faces)

2) Injector (5x5)

ImmiscibleSystem with LiquidPhase, VaporPhase

∈ MultiSegmentWell [Injector] (2 nodes, 1 segments, 1 perforations)

3) Producer (14x14)

ImmiscibleSystem with LiquidPhase, VaporPhase

∈ MultiSegmentWell [Producer] (5 nodes, 4 segments, 4 perforations)

4) Facility (2x2)

JutulDarcy.PredictionMode()

∈ WellGroup([:Injector, :Producer], true, true)

cross_terms:

1) Injector <-> Reservoir (Eq: mass_conservation)

JutulDarcy.ReservoirFromWellFlowCT

2) Producer <-> Reservoir (Eq: mass_conservation)

JutulDarcy.ReservoirFromWellFlowCT

3) Injector -> Facility (Eq: control_equation)

JutulDarcy.FacilityFromWellFlowCT

4) Facility -> Injector (Eq: mass_conservation)

JutulDarcy.WellFromFacilityFlowCT

5) Producer -> Facility (Eq: control_equation)

JutulDarcy.FacilityFromWellFlowCT

6) Facility -> Producer (Eq: mass_conservation)

JutulDarcy.WellFromFacilityFlowCT

Model storage will be optimized for runtime performance.The model is an instance of the MultiModel from Jutul where a submodel is defined for the reservoir, each of the wells and the facility that controls both wells. In addition we can see the cross-terms that couple these wells together. If we want to see more details on how either of these are set up, we can display for example the reservoir model.

reservoir = model[:Reservoir]SimulationModel:

Model with 200 degrees of freedom, 200 equations and 770 parameters

domain:

DiscretizedDomain with MinimalTPFATopology (100 cells, 235 faces) and discretizations for mass_flow, heat_flow

system:

ImmiscibleSystem with LiquidPhase, VaporPhase

context:

DefaultContext(BlockMajorLayout(false), 1000, 1)

formulation:

FullyImplicitFormulation()

data_domain:

DataDomain wrapping CartesianMesh (3D) with 5x5x4=100 cells with 17 data fields added:

100 Cells

:permeability => 100 Vector{Float64}

:porosity => 100 Vector{Float64}

:rock_thermal_conductivity => 100 Vector{Float64}

:fluid_thermal_conductivity => 100 Vector{Float64}

:rock_density => 100 Vector{Float64}

:cell_centroids => 3×100 Matrix{Float64}

:volumes => 100 Vector{Float64}

235 Faces

:neighbors => 2×235 Matrix{Int64}

:areas => 235 Vector{Float64}

:normals => 3×235 Matrix{Float64}

:face_centroids => 3×235 Matrix{Float64}

470 HalfFaces

:half_face_cells => 470 Vector{Int64}

:half_face_faces => 470 Vector{Int64}

130 BoundaryFaces

:boundary_areas => 130 Vector{Float64}

:boundary_centroids => 3×130 Matrix{Float64}

:boundary_normals => 3×130 Matrix{Float64}

:boundary_neighbors => 130 Vector{Int64}

primary_variables:

1) Pressure ∈ 100 Cells: 1 dof each

2) Saturations ∈ 100 Cells: 1 dof, 2 values each

secondary_variables:

1) PhaseMassDensities ∈ 100 Cells: 2 values each

-> ConstantCompressibilityDensities as evaluator

2) TotalMasses ∈ 100 Cells: 2 values each

-> TotalMasses as evaluator

3) RelativePermeabilities ∈ 100 Cells: 2 values each

-> BrooksCoreyRelativePermeabilities as evaluator

4) PhaseMobilities ∈ 100 Cells: 2 values each

-> JutulDarcy.PhaseMobilities as evaluator

5) PhaseMassMobilities ∈ 100 Cells: 2 values each

-> JutulDarcy.PhaseMassMobilities as evaluator

parameters:

1) Transmissibilities ∈ 235 Faces: Scalar

2) TwoPointGravityDifference ∈ 235 Faces: Scalar

3) PhaseViscosities ∈ 100 Cells: 2 values each

4) FluidVolume ∈ 100 Cells: Scalar

equations:

1) mass_conservation ∈ 100 Cells: 2 values each

-> ConservationLaw{:TotalMasses, TwoPointPotentialFlowHardCoded{Vector{Int64}, Vector{@NamedTuple{self::Int64, other::Int64, face::Int64, face_sign::Int64}}}, Jutul.DefaultFlux, 2}

output_variables:

Pressure, Saturations, TotalMasses

extra:

OrderedCollections.OrderedDict{Symbol, Any} with keys: Symbol[]We can see that the model contains primary variables, secondary variables (sometimes referred to as properties) and static parameters in addition to the system we already set up. These can be replaced or modified to alter the behavior of the system.

Replace the density function with our custom version

Let us change the definition of phase mass densities for our model. We'd like to model our liquid phase as weakly compressible and the vapor phase with more significant compressibility. A common approach is to define densities

This is already implement in Jutul and we simply need to instantiate the variable definition:

c = [1e-6/bar, 1e-4/bar]

ρ = ConstantCompressibilityDensities(p_ref = 1*bar, density_ref = rhoS, compressibility = c)ConstantCompressibilityDensities (ref_dens=[1000.0, 100.0] kg/m^3, ref_p=[1.0, 1.0] bar)Before replacing it in the model. This change will propagate to all submodels that have a definition given for PhaseMassDensities, including the wells. The facility, which does not know about densities, will ignore it.

replace_variables!(model, PhaseMassDensities = ρ);This concludes the setup of the model.

Set up initial state

The model is time-dependent and requires initial conditions. For the immiscible model it is sufficient to specify the reference phase pressure and the saturations for both phases, summed up to one. These can be specified per cell or one for the entire grid. Specifying a single pressure for the entire model is not very realistic, but should be fine for our simple example. The initial conditions will equilibrate themselves from gravity fairly quickly.

state0 = setup_reservoir_state(model, Pressure = 150*bar, Saturations = [1.0, 0.0])Dict{Any, Any} with 4 entries:

:Producer => Dict{Symbol, Any}(:TotalMassFlux=>[0.0, 0.0, 0.0, 0.0], :PhaseM…

:Injector => Dict{Symbol, Any}(:TotalMassFlux=>[0.0], :PhaseMassDensities=>[…

:Reservoir => Dict{Symbol, Any}(:PhaseMassMobilities=>[0.0 0.0 … 0.0 0.0; 0.0…

:Facility => Dict{Symbol, Any}(:TotalSurfaceMassRate=>[0.0, 0.0], :WellGroup…Set up report time steps and injection rate

We create a set of time-steps. These are report steps where the solution will be reported, but the simulator itself will do internal subdivision of time steps if these values are too coarse for the solvers. We also define an injection rate of a full pore-volume (at reference conditions) of gas.

dt = repeat([30.0]*day, 12*5)

pv = pore_volume(model, parameters)

inj_rate = sum(pv)/sum(dt)0.19290123456790123Set up well controls

We then set up a total rate target (positive value for injection) together with a corresponding injection control that specifies the mass fractions of the two components/phases for pure gas injection, with surface density given by the known gas density. The producer operates at a fixed bottom hole pressure. These are given as a Dict with keys that correspond to the well names.

rate_target = TotalRateTarget(inj_rate)

I_ctrl = InjectorControl(rate_target, [0.0, 1.0], density = rhoGS)

bhp_target = BottomHolePressureTarget(50*bar)

P_ctrl = ProducerControl(bhp_target)

controls = Dict()

controls[:Injector] = I_ctrl

controls[:Producer] = P_ctrl

# Set up the forcesProducerControl{BottomHolePressureTarget{Float64}, Float64}(BottomHolePressureTarget with value 50.0 [bar], 1.0)Set up forces for the whole model. For this example, all other forces than the well controls are defaulted (amounting to no-flow for the reservoir). Jutul supports either a single set of forces for the entire simulation, or a vector of equal length to dt with varying forces. Reasonable operational limits for wells are also set up by default.

forces = setup_reservoir_forces(model, control = controls)Dict{Symbol, Any} with 4 entries:

:Producer => (mask = nothing,)

:Injector => (mask = nothing,)

:Reservoir => (bc = nothing, sources = nothing)

:Facility => (control = Dict{Any, Any}(:Producer=>ProducerControl{BottomHole…Simulate the model

We are finally ready to simulate the model for the given initial state state0, report steps dt, parameters and forces. As the model is small, barring any compilation time, this should run in about 300 ms.

result = simulate_reservoir(state0, model, dt, parameters = parameters, forces = forces)ReservoirSimResult with 60 entries:

wells (2 present):

:Producer

:Injector

Results per well:

:Vapor_mass_rate => Vector{Float64} of size (60,)

:lrat => Vector{Float64} of size (60,)

:orat => Vector{Float64} of size (60,)

:control => Vector{Symbol} of size (60,)

:bhp => Vector{Float64} of size (60,)

:Liquid_mass_rate => Vector{Float64} of size (60,)

:mass_rate => Vector{Float64} of size (60,)

:rate => Vector{Float64} of size (60,)

:grat => Vector{Float64} of size (60,)

states (Vector with 60 entries, reservoir variables for each state)

:Saturations => Matrix{Float64} of size (2, 100)

:Pressure => Vector{Float64} of size (100,)

:TotalMasses => Matrix{Float64} of size (2, 100)

time (report time for each state)

Vector{Float64} of length 60

result (extended states, reports)

SimResult with 60 entries

extra

Dict{Any, Any} with keys :simulator, :config

Completed at Oct. 01 2024 16:10 after 758 milliseconds, 601 microseconds, 954 nanoseconds.Unpacking the result

The result contains a lot of data. This can be unpacked to get the most typical desired outputs: Well responses, reservoir states and the time they correspond to.

wd, states, t = resultReservoirSimResult with 60 entries:

wells (2 present):

:Producer

:Injector

Results per well:

:Vapor_mass_rate => Vector{Float64} of size (60,)

:lrat => Vector{Float64} of size (60,)

:orat => Vector{Float64} of size (60,)

:control => Vector{Symbol} of size (60,)

:bhp => Vector{Float64} of size (60,)

:Liquid_mass_rate => Vector{Float64} of size (60,)

:mass_rate => Vector{Float64} of size (60,)

:rate => Vector{Float64} of size (60,)

:grat => Vector{Float64} of size (60,)

states (Vector with 60 entries, reservoir variables for each state)

:Saturations => Matrix{Float64} of size (2, 100)

:Pressure => Vector{Float64} of size (100,)

:TotalMasses => Matrix{Float64} of size (2, 100)

time (report time for each state)

Vector{Float64} of length 60

result (extended states, reports)

SimResult with 60 entries

extra

Dict{Any, Any} with keys :simulator, :config

Completed at Oct. 01 2024 16:10 after 758 milliseconds, 601 microseconds, 954 nanoseconds.We could in fact equally well have written wd, states, t = simulate_reservoir(...) to arrive at the same result.

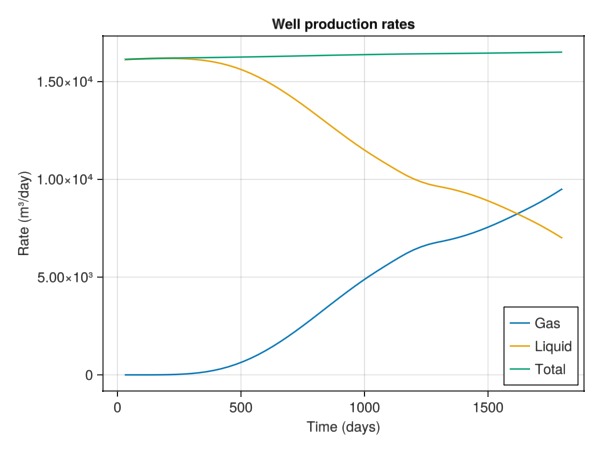

Plot the producer responses

We load a plotting package to plot the wells.

using GLMakiePlot the surface rates at the producer

We observe that the total rate does not vary much, but the composition changes from liquid to gas as the front propagate through the domain and hits the producer well. Gas rates

qg = wd[:Producer][:grat]60-element Vector{Float64}:

-1.0164087227932228e-9

-8.16219309693118e-8

-7.540131352500176e-7

-6.270934816565255e-6

-2.306818471725421e-5

-6.18880702755119e-5

-0.00013782003035443064

-0.0002701518870632601

-0.000481719968787884

-0.0007977376546362535

⋮

-0.09129007147413713

-0.09333734976385764

-0.09545169295083995

-0.09762088906887735

-0.09984679484523344

-0.10219129999923354

-0.10470151887139778

-0.1073274048356803

-0.11010422209014536Total rate

qt = wd[:Producer][:rate]60-element Vector{Float64}:

-0.1867323905983157

-0.18691761919338537

-0.1871043867184039

-0.18724909577432933

-0.18735950073776086

-0.18744486026780752

-0.1875169140328297

-0.18758176482203434

-0.1876526294892619

-0.18772333168138772

⋮

-0.190621240402773

-0.1906771777847073

-0.19073191661051214

-0.19078367423678286

-0.1908331007203114

-0.19088804086079791

-0.19095469131572654

-0.1910216514161509

-0.1910898887756575Compute liquid rate and plot

ql = qt - qg

x = t/day

fig = Figure()

ax = Axis(fig[1, 1], xlabel = "Time (days)",

ylabel = "Rate (m³/day)",

title = "Well production rates")

lines!(ax, x, abs.(qg).*day, label = "Gas")

lines!(ax, x, abs.(ql).*day, label = "Liquid")

lines!(ax, x, abs.(qt).*day, label = "Total")

axislegend(position = :rb)

fig

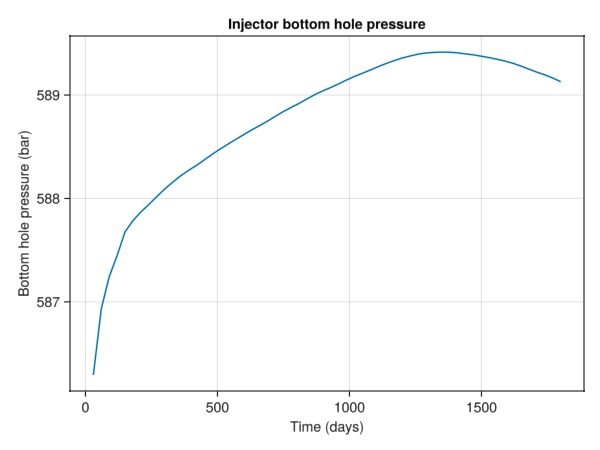

Plot bottom hole pressure of the injector

The pressure builds during injection, until the gas breaks through to the other well.

bh = wd[:Injector][:bhp]

fig = Figure()

ax = Axis(fig[1, 1], xlabel = "Time (days)",

ylabel = "Bottom hole pressure (bar)",

title = "Injector bottom hole pressure")

lines!(ax, x, bh./bar)

fig

Example on GitHub

If you would like to run this example yourself, it can be downloaded from the JutulDarcy.jl GitHub repository as a script, or as a Jupyter Notebook

This page was generated using Literate.jl.